Key Decisions for New Electronics Manufacturing Founders

Starting a business in electronics manufacturing involves high-cost tools, long lead times, and complex quality requirements. Founders often rush into production without setting up the right systems for consistency, visibility, or scale. It’s not just about building a product — it’s about building a durable operation that can deliver. From design to delivery, the choices you make early affect your cost structure, vendor relationships, and credibility. This article outlines seven decision areas that can help first-time entrepreneurs navigate the early stages of building a manufacturing company.

Establish a Professional Digital Presence

Buyers, suppliers, and investors often evaluate your business based on what they see online. Electronics companies without a strong web presence may struggle to build trust, especially during early outreach. A clear and functional website can help position your offering, explain technical capabilities, and attract talent. Olive Street Design builds digital platforms, helping businesses align their brand with their operations. For founders, this step supports credibility across channels.

Plan for Production System Efficiency

Early-stage manufacturers benefit from systems that reduce manual intervention and improve repeatability. Automating key processes can lower error rates, support compliance, and shorten delivery timelines. These benefits increase as order volumes grow, especially when multiple product variations are involved. Choosing automation control systems with real-time integration and global deployment options can support long-term growth. These platforms enable consistent production without the overhead of large teams.

Design Prototypes with Flexibility in Mind

Prototypes are essential, but they don’t need to be perfect. Their purpose is to test functionality, tolerance, and potential edge cases — not to finalize a product. By allowing room for revision, you reduce the risk of retooling and late-stage design delays. Document every change and clarify what feedback will influence the next version. Flexible prototyping shortens the path to production without locking you into early assumptions.

Align Capacity with Demand Signals

Scaling production too quickly can increase overhead, while waiting too long may lead to lost opportunities. Evaluate how many units you can build reliably with your current tools and team. Assess when to invest in equipment upgrades or contract support based on consistent order volume, not one-time spikes. Build a simple model that maps expected demand against current throughput. This helps you prepare for growth without overextending.

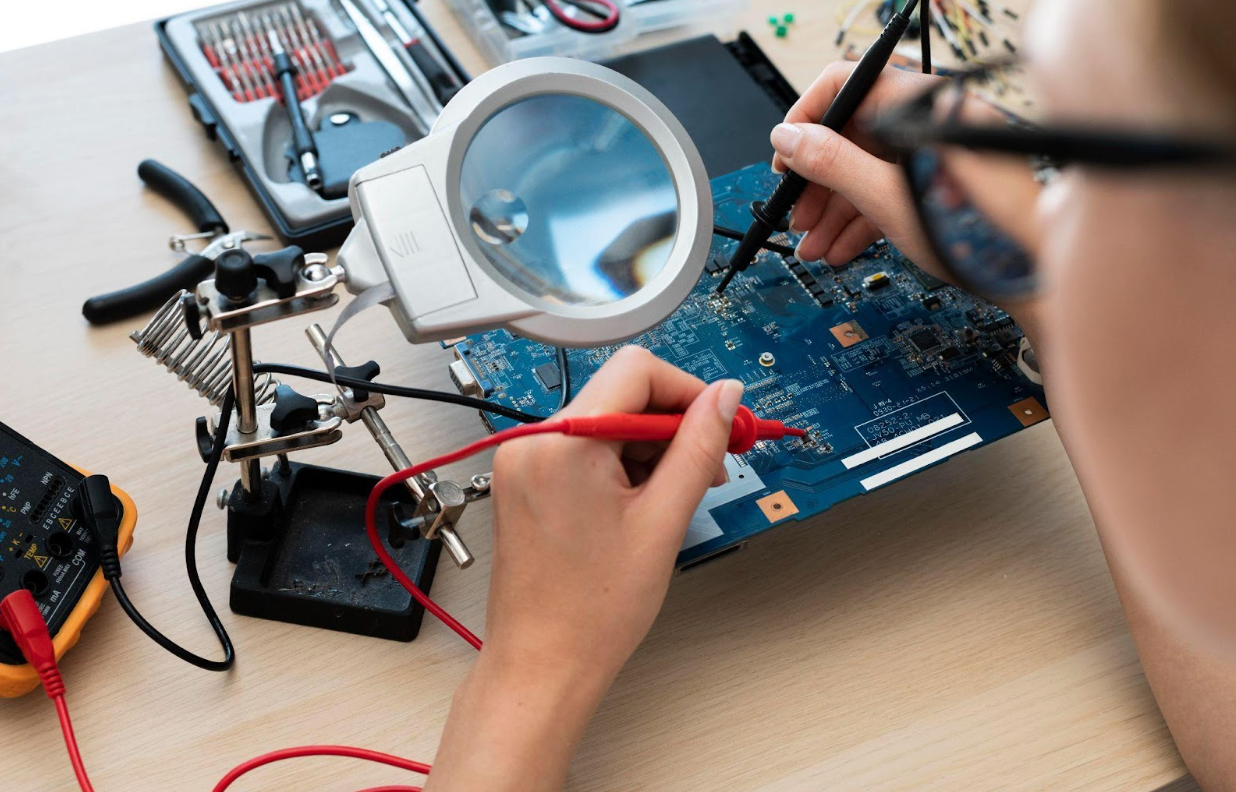

Evaluate Integration Versus Outsourcing

Not every task needs to be kept in-house, but critical processes may benefit from tighter control. Consider whether integrating certain steps — like PCB assembly or testing — improves your quality or speed. Weigh these decisions against setup cost, staffing needs, and long-term volume. Vertical integration makes sense when it protects delivery timelines or reduces interdependencies. Document your reasons clearly before committing.

Select Vendors for Reliability and Fit

Suppliers influence your timelines, pricing, and final product quality. When choosing partners, go beyond pricing and evaluate responsiveness, flexibility, and communication. Consider starting with smaller runs to test consistency before committing to a larger contract. Ask questions about lead time buffers, change requests, and production ramp plans. A dependable vendor relationship reduces surprises and supports steady growth.

Address Cost Pressures Strategically

Managing costs is a constant concern, especially for new entrants competing with larger firms. Focus first on areas where simplification or standardization can lower expenses without reducing quality. This might include reducing part variations, redesigning enclosures, or combining steps in the assembly process. Avoid shortcuts that compromise product integrity or testing. Strategic cost management builds a more resilient margin structure over time.

Electronics manufacturing demands precise execution, especially in the early stages of a new venture. Founders who focus on system reliability, operational clarity, and supplier fit are more likely to meet delivery goals and scale effectively. Decisions about automation, branding, design, and capacity have long-term implications — and it's worth slowing down to get them right. The right infrastructure and processes give even small teams the ability to compete. Keep your systems transparent, your vendors aligned, and your costs under control. These early decisions become the framework that supports everything that follows.

Discover how Olive Street Design can transform your online presence with award-winning, AI-optimized websites. Elevate your brand today!